Flow modeling for mold filling using computational fluid dynamics

FLOWCast™ is the fluid flow modeling module from Finite Solutions, Inc.

- Works with SOLIDCast™ models to simulate metal movement through gating and mold filling.

- Models convection, conduction & radiation to predict flow-related defects (misruns, oxides, splashing).

- View temperature, velocity & pressure progression; composite plots of fill timing and temperatures.

- Integrated with SOLIDCast for seamless CAD import or in-app model building & meshing.

- Site licensed; unlimited parallel simulations leveraging multi-core hardware.

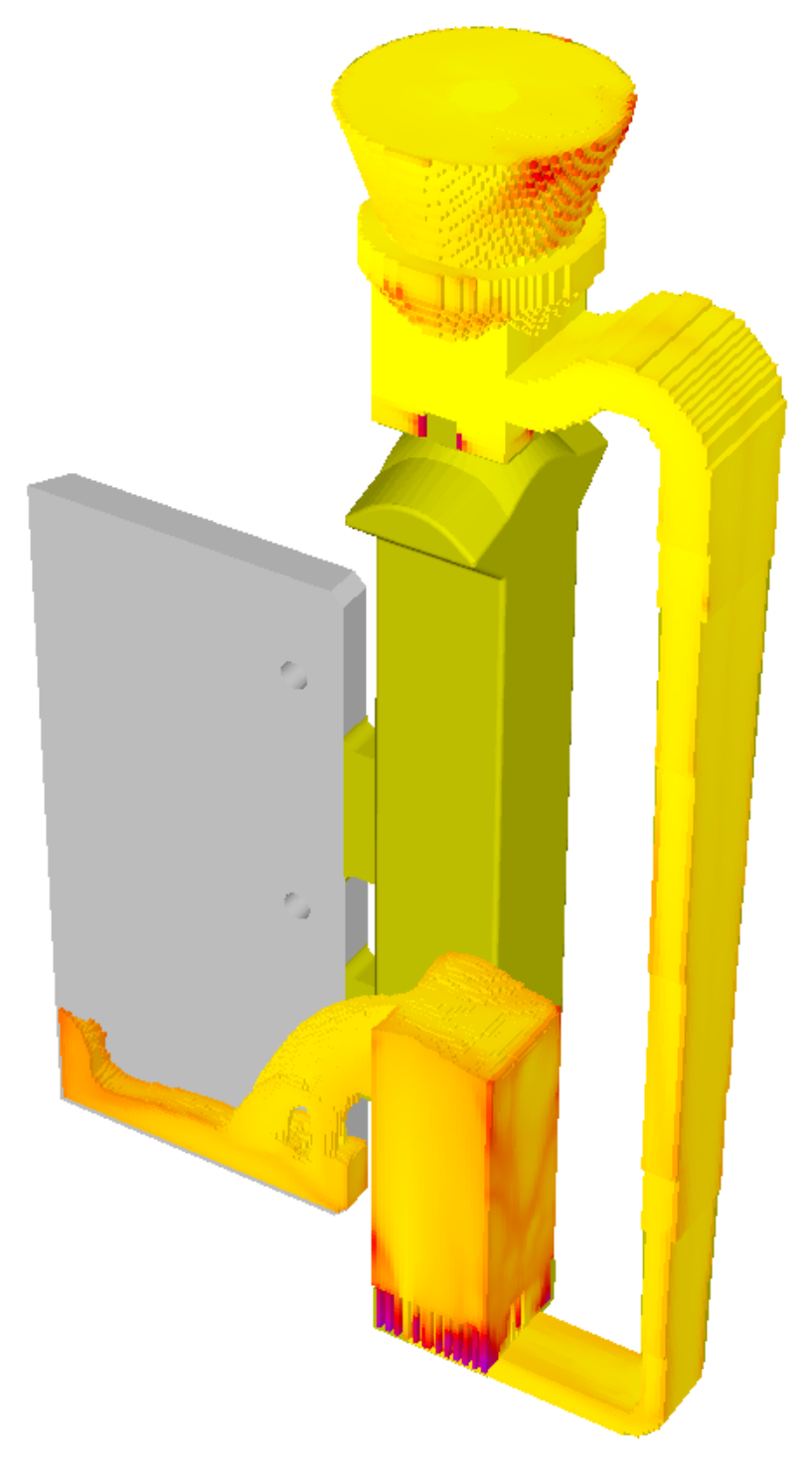

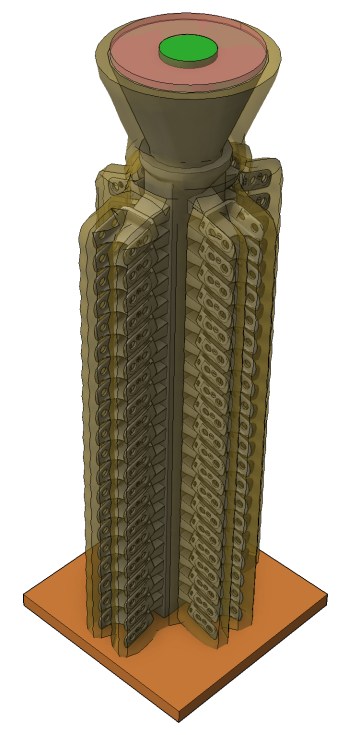

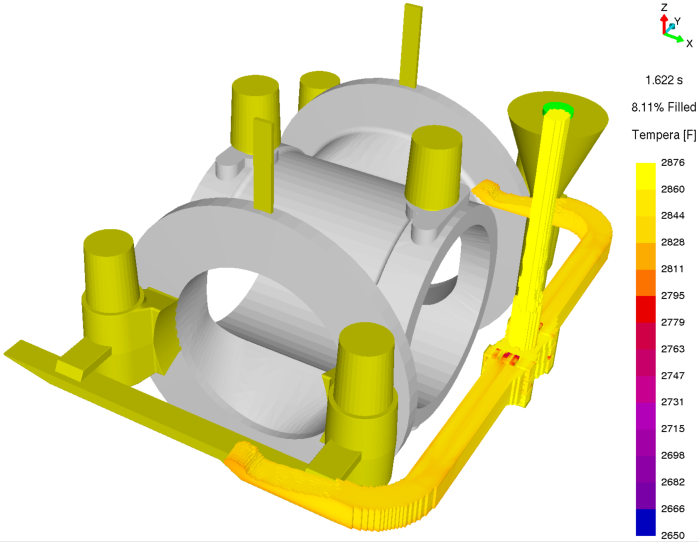

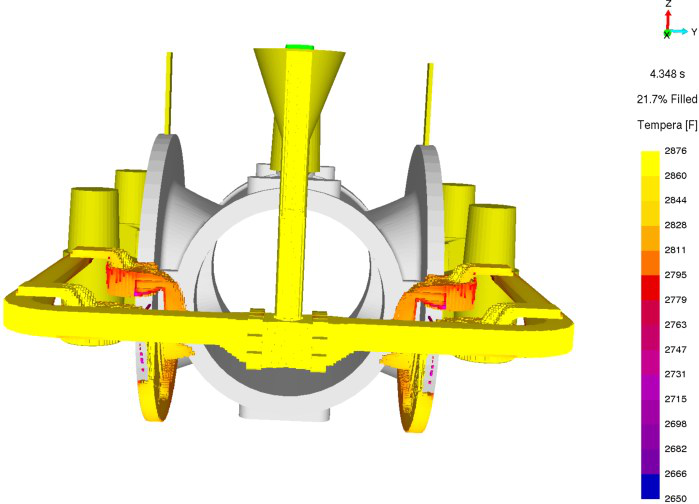

Sand Casting

Full model of a steel valve body. Fill material, ceramic filters, chills and exothermic riser sleeves.

Initial filling of the gating system, including flow through a ceramic filter.

End view, showing metal cooling as it enters the casting cavity and metal splash as it drops.

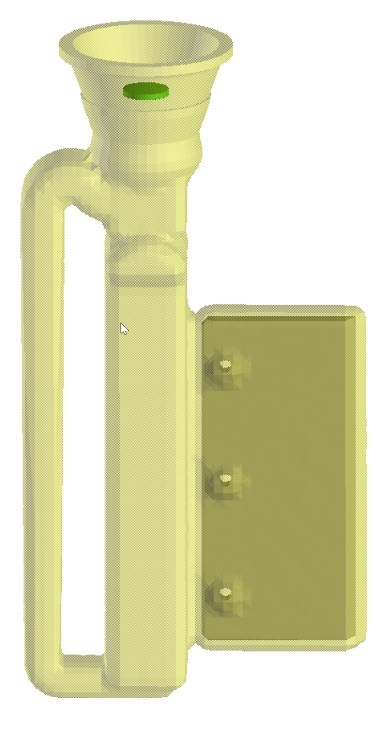

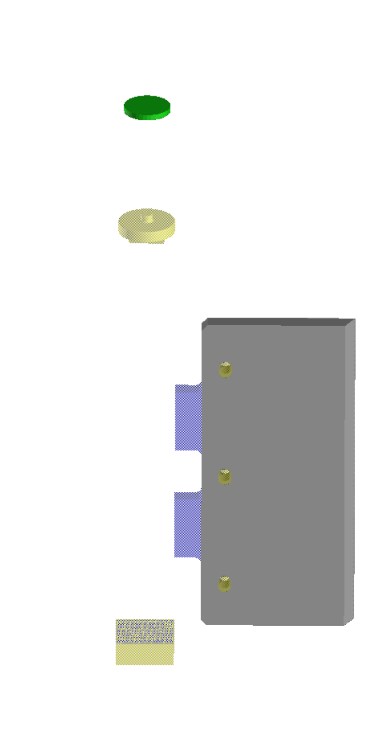

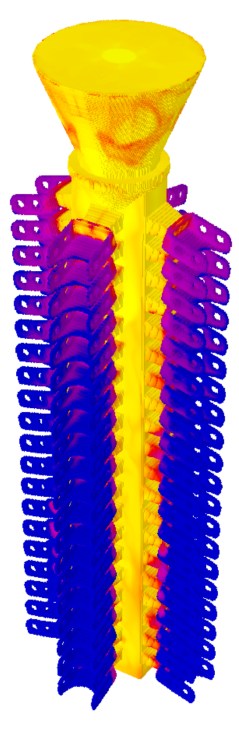

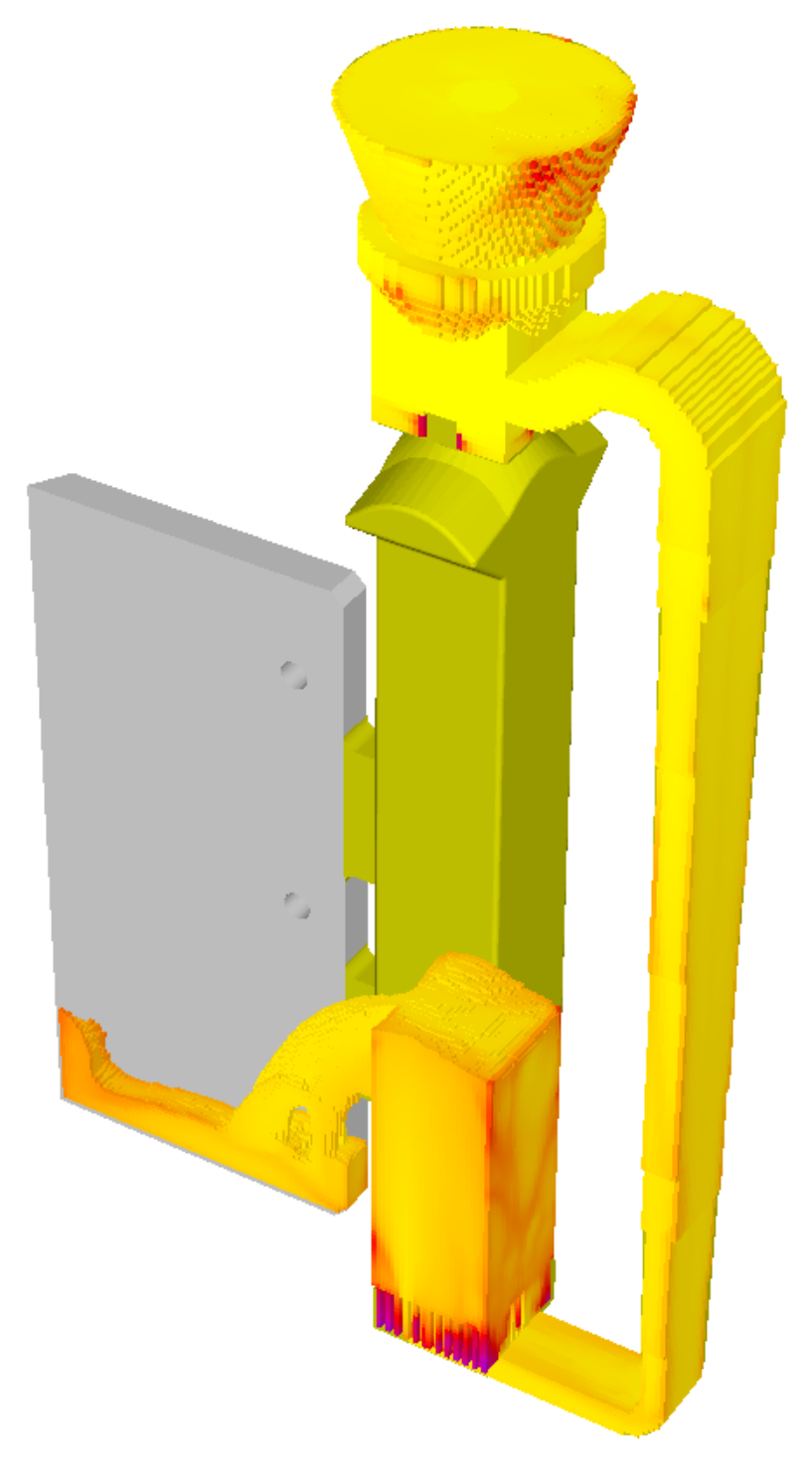

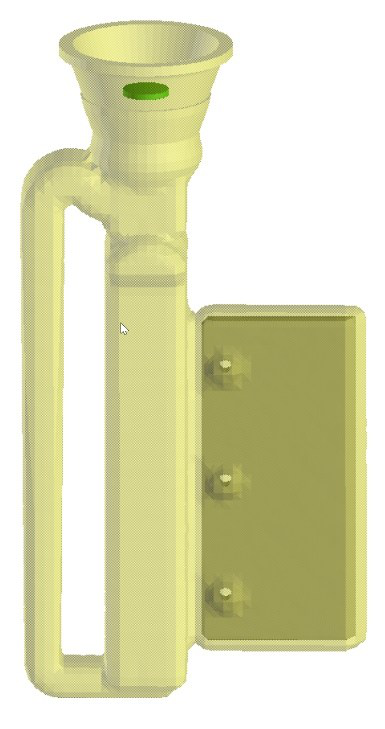

Investment Casting

Full model with shell on the left; fill material, ceramic plug and filter on the right.

Filling sequence showing effects of ceramic plug diversion and filter cleaning before feeder bar.

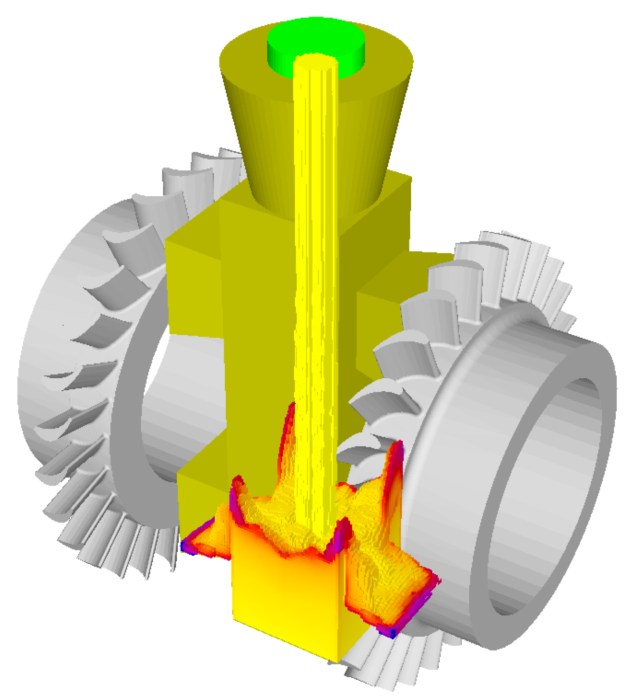

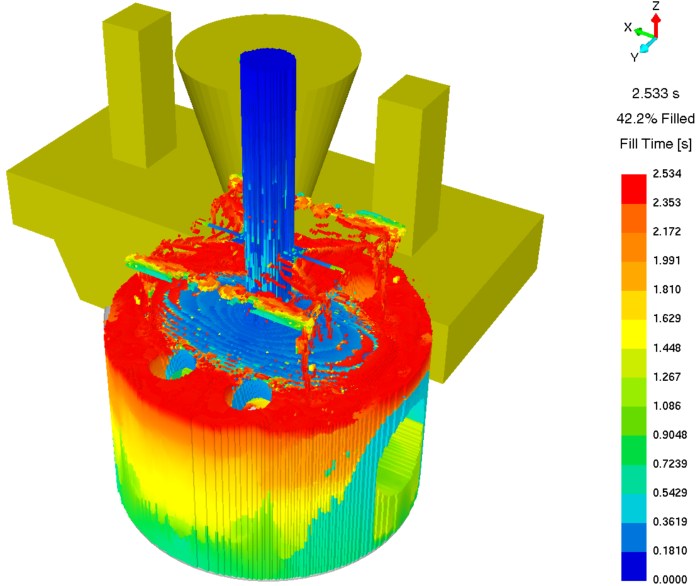

Initial surge through lower gates of an investment cast rotor.

Temperature losses during filling of a tree with sand bed and exothermic hot topping.

Fill-time plot mapping when each area first received metal.

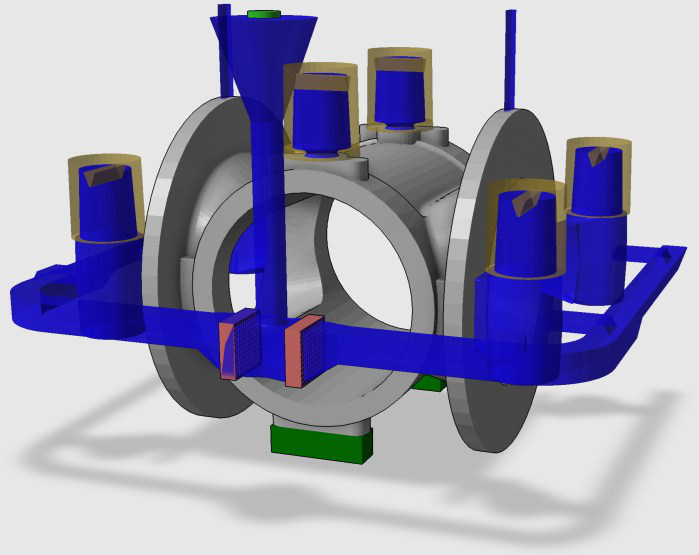

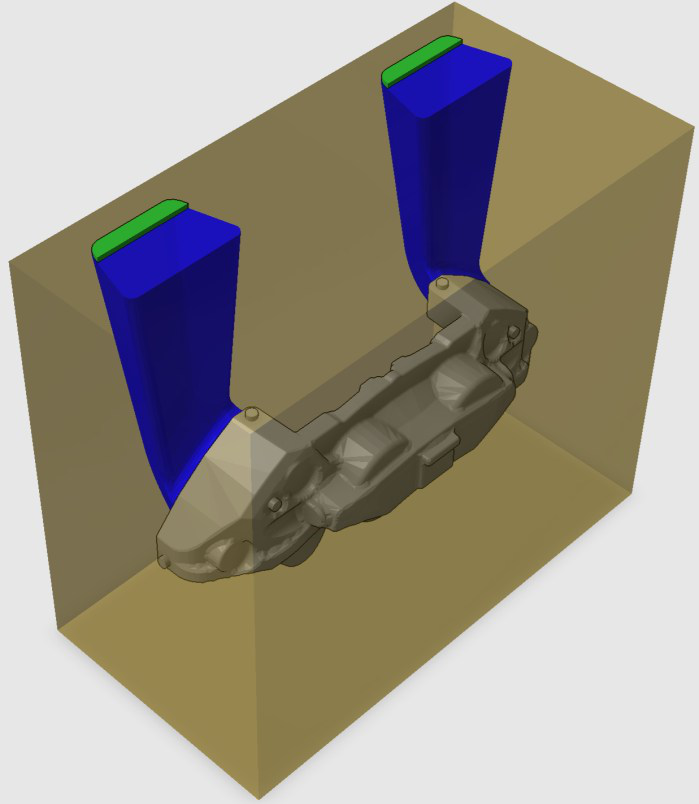

Permanent Mold Casting

Full model of an aluminum tilt-pour casting; fill material, risers, and preheated die.

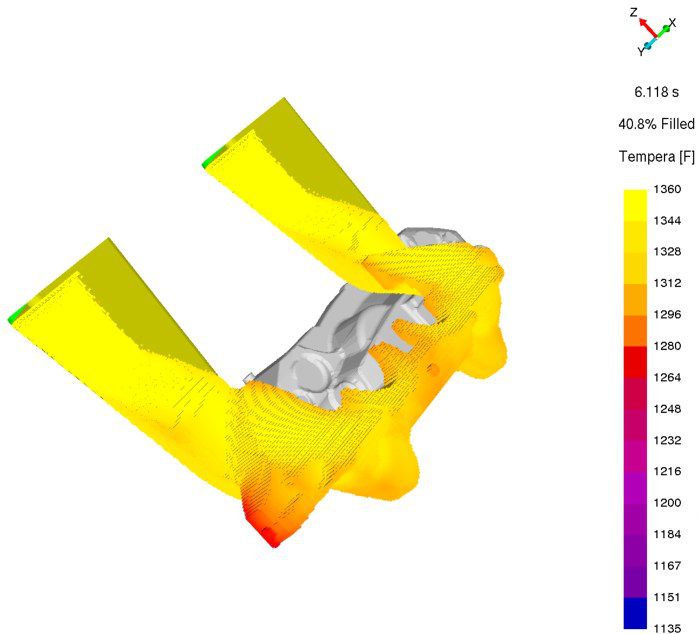

Temperature and velocity during tilt-pour.

Fixed volume fill model showing metal transfer from cup to die.